JBB Series electric mechanical diaphragm metering dosing pump for chemical fluids

- Model Number: JBB25/1.0

- Brand Name: kenshine-pump

- Place of Origin: Shanghai, China

- Minimum Order Quantity: 1set

- Supply Capacity: 500Sets per month/month

- Payment: T/T in advance

- MemberShip: Free Member

- Inquiry Now

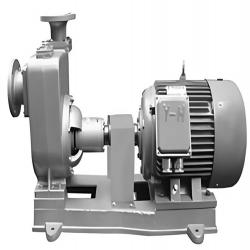

JBB25/1.0 JBB Series electric mechanical diaphragm metering dosing pump for chemical fluids Description

The hydraulic end of JBB series mechanical diaphragm metering pump uses the diaphragm to form a working chamber, and the reciprocating motion of the piston (plunger) is replaced by the periodic deformation of the diaphragm, which is called the mechanical diaphragm metering pump.

characteristic:

1 - No dynamic seal and leakage.

Because the static seal of the diaphragm at the hydraulic end replaces the dynamic seal of the piston, it can ensure no leakage when transporting media;

2 - In addition to clean water, it is more suitable for conveying flammable, explosive, highly toxic, malodorous and radioactive media;

3 - It is simpler in structure than the hydraulic diaphragm pump, but more complex than the plunger pump;

4 - Digital controller of metering pump can be equipped to realize digitalization, local and remote control;

5 - The diaphragm is made of five layers of composite structure (the first layer is super tough acid resistant film, the second layer is elastic rubber, the third layer is supporting iron core, the fourth layer is reinforced nylon fiber cloth, and the fifth layer is completely covered with elastic rubber), which can effectively improve the service life of the diaphragm;

6 - The stainless-steel strong plate design is added behind the diaphragm to improve the service life of the diaphragm.

7 - The outlet pressure is generally below 1.0Mpa, and the applicable range of flow is small; The metering accuracy is lower than that of plunger pump and hydraulic diaphragm pump.

When the pressure is small to large, the flow change can reach 10%.

Application:

Diaphragm metering pumps have a wide range of applications, ranging from ordinary normal temperature clean water to media with strong corrosion, volatility, crystallization, flammability, explosion, highly toxic odor and heavy, medium viscosity, radioactivity, etc., and can also transport suspended liquids.

In order to prevent accidents caused by mixing medium and hydraulic oil after diaphragm rupture, double diaphragm metering pump with diaphragm rupture alarm device can be selected for flammable, explosive, highly toxic and precious liquids.

Flow range: 0-130 L/H

Pressure range: 0-1.0MPA

Motor power: 60W, 220V/380V/110V/24V, 50/60Hz

Drive system: two-phase, three-phase standard motor or explosion-proof motor

Protection grade: IP55, IP54, Material:

Pump head: SUS304, SUS316, PVC, PTFE

Diaphragm: PTFE

Check valve: SUS304, SUS316, PVC, PTFE

Valve ball: ZrO2, SUS304, SUS316, ceramic

Working conditions

Ambient temperature: - 30 ℃ - 80 ℃

| flow rate | 0-130L/H |

|---|---|

| pressure | 0-1MPA |

| pump material | SS304, SS316, PVC, PTFE |

| chemical dosing pump | mechanical diaphragm pump |

| metering dosing pump | industrial pump |

| chemical pump | electric diaphragm pump |

| Stainless steel pump | Plastic pump |

| kenshine-pump | china pump |

Retaled category: Other Pump

Hot search: chemical dosing pump, electric diaphragm pump, mechanical diaphragm pump, metering dosing pump, industrial pump, electric mechanical pump