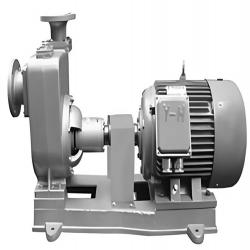

FJX axial flow circulation pump

- Model Number: FJX-250

- Brand Name: kenshine-pump.com

- Place of Origin: Shanghai, China

- Minimum Order Quantity: 1set

- Supply Capacity: 1000sets per month/month

- Payment: T/T in advance

- MemberShip: Free Member

- Inquiry Now

FJX-250 FJX axial flow circulation pump Description

FJX forced circulation axial pumps

FJX series forced circulation pump is for the axial flow pump with high flow and low head. FJX type forced circulation pump adopts international standard manufacturing with high efficiency, energy saving and convenient maintenance etc.

FJX forced circulation axial pumps is used for membrane caustic soda, phosphoric acid, sugar, molten salt, paper, wastewater and other industries evaporation, concentration and cooling etc. In order to improve the production capacity of equipment, increase the heat transfer coefficient of heat exchanger for forced circulation.

Installation type: ground foundation (flexible support can be configured according to users’ requirements) is directly suspended on the evaporator.

Pump type: vertical, horizontal.

Transmission mode: direct connection transmission, belt transmission, hydraulic coupling, universal joint transmission.

Sealing structure: combination mechanical seal, packing seal.

Pump system: casting or welding.

FJX series forced circulation axial flow pump performance range

Flow: 300-23000 m3 / h

Head: 2-7 m

Working pressure: 0.1-0.7 MPA

Operating temperature: -20℃-480℃

FJX series forced circulation axial flow pump

Our company has introduced and absorbed the advantages of similar products at home and abroad and made great adjustments to the product structure to ensure the reliability, economy and safety of the pump.

1. Low speed, generally within 980r/min, consistent with the crystallization process requirements for smooth operation.

2. Excellent hydraulic performance, high efficiency > 70% high efficiency zone width, good cavitation resistance performance.

3. Consider that the flow direction of the pump medium is vertical downward and horizontal downward. The influence of water flow force on pump shaft is great. The subduction force of the medium is transferred to the pump body, thus ensuring the stable operation of the pump, greatly reducing the influence of the medium on the mechanical seal force, and prolonging the service life of the mechanical seal. The improvement of the structure has taken a big step in the domestic similar pumps. In addition, the pump body adopts integral casting with good rigidity and the middle supporting structure is connected stably.

4. The bearing box is a square long-span heavy structure with good stability, strong bearing capacity, reliable operation, convenient and accurate installation compared with similar domestic products (the original domestic bearing box is a split-type).Radial short cylindrical bearings and heavy duty pair bearings are used at both ends. Its bearings are NSK (SKF) or domestic high quality bearings.

5. The shaft seal adopts the combination of the auxiliary impeller power seal and the bergman quick-mounted double-end mechanical seal, which is externally cooled and rinsed to improve the working conditions of the shaft seal and the machine seal life is long. The outer circle of shaft sleeve is enlarged, and the deformation of wall thickness is smaller than that of similar domestic pumps.

| flow rate | 300-23000m3/h |

|---|---|

| head | 2-7m |

| pump material | stainless steel |

| circulation pump | transfer pump |

| chemical pump | industrial pump |

| stainless steel pump | drainage pump |

| cooling pump | sewage pump |

| kenshine-pump | china pump |

Retaled category: Chemical Pump

Hot search: axial flow pump, chemical pump, industrial pump, circulation pump, transfer pump, drainage pump