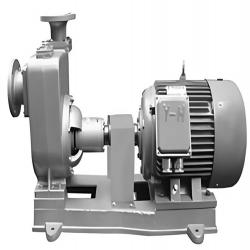

FSB Fluoroplastic alloy chemical transfer pump

- Model Number: 80FSB-25L

- Brand Name: kenshine-pump

- Place of Origin: Shanghai, China

- Minimum Order Quantity: 1SET

- Supply Capacity: 1000Sets per month/month

- Payment: T/T in advance

- MemberShip: Free Member

- Inquiry Now

80FSB-25L FSB Fluoroplastic alloy chemical transfer pump Description

FSB fluorine plastic alloy pump is designed and made according to the international standard. The pump body is made of the metal and FEP (F46) organic combination, pump cover, impeller and shaft sleeve are pressed by molding of fluorine plastic with metal insert. Shaft seal is mounted outside as the bellows mechanical seal. The static ring choose 99% alumina ceramic or silicon nitride, ring with four fluorine filling materials has the good corrosion resistance.

FSB fluorine plastic alloy chemical transfer centrifugal pump is suitable for conveying the sulfuric acid, hydrochloric acid, acetic acid, hydrofluoric acid, nitric acid and aqua regia, strong alkali, strong oxidizing agents, organic solvents, antioxidant and other harsh condition of strong corrosive medium with any concentration.

Fluorine plastic is currently one of the world's most strong corrosion resistant material. Prevent running, rising, dropping, leakage. FSB fluorine plastic alloy pump is widely used in chemical industry, acid, alkali, smelting, rare earth, pesticide, dye, medicine, paper, electroplating, electrolysis, pickling, electronic components, scientific research institutions and other industries.

Fluorine plastic alloy centrifugal pump

50 the FSB - 30 D/L

50 : inlet diameter (mm)

FS :fluorine plastic material

B : single-stage single-suction cantilever centrifugal pump

30:head (m)

D :close coupling

L:Shaft coupling

Fluorine plastic alloy centrifugal pump features:

FSB type fluorine plastic alloy pump consists of pump body, impeller, cover, seal, bracket, pump shaft, coupling shaft, lifting bolt, nut, bottom plate, etc.

1, pump body: left and right sides of the connection department embedded steel flange ring each one molded plastic alloy. It has the advantages of compact and reasonable structure, strong corrosion resistance, tight and reliable sealing function, stable work, low noise, high mechanical strength, no aging, no toxin decomposition, easy maintenance, smooth runner, high efficiency, energy saving and so on.

2. A stainless steel (1Cr18Ni9Ti) alloy is embedded in the right side of the gland.

3. Impeller: adopt the connection method of connecting shaft. The metal shaft is made of high-quality steel round processing and is formed by fluoroplastic pressing at high temperature.

4. Mechanical seal: WB2 type, ST type adjustable single end mechanical seal without cooling water is adopted, which is made of silicon carbide, high-purity alumina ceramics, filled tetrafluorin, graphite and other materials

| Flow rate | 2-100m3/h |

|---|---|

| Head | 3-80m |

| pump material | fluorine plastic alloy |

| centrifugal pump | chemical pump |

| transfer pump | circulating pump |

| corrosion resistant pump | acid pump |

| alkali pump | solvent pump |

| china pump | kenshine-pump |

Retaled category: Chemical Pump

Hot search: centrifugal pump, chemical pump, transfer pump, circulating pump, corrosive resistant pump, acid pump