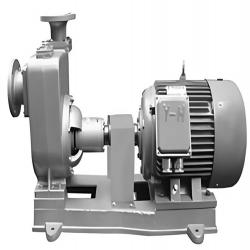

IS Single stage end suction cantilever centrifugal pump

- Model Number: IS80-65-160

- Brand Name: kenshine-pump.com

- Place of Origin: Shanghai, China

- Minimum Order Quantity: 1Set

- Supply Capacity: 1000Sets per month/month

- Payment: T/T IN ADVANCE

- MemberShip: Free Member

- Inquiry Now

IS80-65-160 IS Single stage end suction cantilever centrifugal pump Description

IS single stage single suction (axial suction) cantilever centrifugal pump, is designed and manufactured as the energy saving pump on the base of BA, B and other single-stage clean water centrifugal pump.

Advantages:

Reasonable hydraulic performance, wide application range, convenient maintenance, high Efficiency, energy saving, low cost etc.

IS single stage end suction cantilever centrifugal pump is suitable for industrial and urban water supply and drainage, but also for agricultural drainage and irrigation etc. IS end suction centrifugal pump is used to convey clean water or other liquids with similar physical and chemical properties to clean water. Liquid temperature is not higher than 105℃. Pump material; cast iron, stainless steel, bronze impeller etc. Normal temperature type is for clean water or similar liquid not higher than 80Degree Celsius. Hot water type is for the hot water or similar liquids no higher than 105DegrrCelsus.

Features:

1. IS end suction centrifugal pump is designed according to the performance and size stipulated by the international standard ISO2858. The pump is mainly composed of pump body, pump cover, impeller, shaft, seal ring, axle sleeve and suspension bearing.

2, Pump body and pump cover and impeller can be pull out back (back door structure).Its advantage is convenient maintenance. Maintenance does not move the pump body, suction pipe, discharge pipe and motor, just remove the extension shaft coupling of the middle connection, can exit the rotor part for maintenance.

3, Pump shell (he pump body and pump cover) consist of working chamber. The impeller, shaft and rolling bearing are the rotor of the pump. The suspension bearing component supports the rotor part of the pump, and the rolling bearing receives the radial and axial forces of the pump.

4, in order to balance the axial force of the pump, the impeller front, after are equipped with a seal ring, and in the impeller rear cover plate is equipped with a balance hole.

5, packing seal or mechanical seal

6. In order to avoid shaft wear, the shaft is protected by shaft sleeve with O ring.

7. The transmission mode of the pump is connected with the motor by an extended elastic coupling. The rotation direction of the pump is clockwise when seen from the driving end,

| flow rate | 2-200m3/h |

|---|---|

| head | 3-125m |

| pump material | cast iron or stainless steel |

| centrifugal pump | transfer pump |

| booster pump | single stage pump |

| water pump | irrigation pump |

| supply water pump | drainage pump |

| kenshine-pump | china pump |

Retaled category: Centrifugal Pump

Hot search: centrifugal pump, transfer pump, water pump, booster pump, supply water pump, irrigation pump