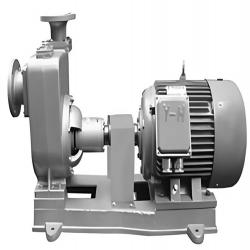

IS,IR Single stage end suction centrifugal water pump

- Model Number: IS125-100-315

- Brand Name: kenshine-pump

- Place of Origin: Shanghai, China

- Minimum Order Quantity: 1SET

- Supply Capacity: 1000Sets per month/month

- Payment: T/T in advance

- MemberShip: Free Member

- Inquiry Now

IS125-100-315 IS,IR Single stage end suction centrifugal water pump Description

IS single stage single suction (axial suction) centrifugal pump is the developed energy saving pump at the base of BA, B and other single stage clean water centrifugal pump . The advantages of single stage single suction centrifugal pump: the whole series of hydraulic performance layout is reasonable and the user choice range is wide and convenient maintenance an the efficiency and suction range reach the international average advanced level.

IS Single stage single suction centrifugal pump is suitable for industrial and urban water supply and drainage and it also can be used for agricultural irrigation and drainage and for transporting clean water or other liquid with physical and chemical properties similar to clean water. The temperature of liquids is not high 80 degree Celsius

IS,IR horizontal single stage single suction centrifugal water pump is used for industry, agriculture and urban, drainage, fire water supply and so on. The pump is specialized for the absorption and delivery of clean water and other liquids similar to water with physical and chemical properties and the liquid does not contain solid particles.

It is widely used in industry, agriculture, city, drainage, fire and water supply, etc. IS and IR pumps are designed according to the performance and size specified in international standard IS02858.It is one of the energy-saving pump products promoted in China. The pump features simple structure, reliable performance, small size, light weight, good cavitation resistance, low power consumption and easy maintenance.

IS and IR pumps are widely used. There are 140 kinds of pumps in the whole series, but only four kinds of shafts are used. The same specification of shaft, bearing, shaft seal, interchangeable; The whole series of pump suspension also only four kinds. Pump speed is divided into 2900 and 1450 RPM two kinds. Performance is as follows: 2900rpm 1450 RPM large flow rate: 240m 3/min 400m 3/min high total head: 125m 55m high speed: 3500 RPM (used for 60 wave regulating power supply, impeller diameter has been reduced)

Product features

1. IS single-stage single-suction centrifugal pump IS designed according to the performance and size specified in international standard ISO2858. It IS mainly composed of pump body, pump cover, impeller, shaft, sealing ring, shaft sleeve and suspension bearing.

2, IS type single-stage single-suction centrifugal pump body and pump cover part, IS split from the back of the impeller. That IS, the back door structure. Its advantage is convenient maintenance, maintenance of the pump body, suction pipe, discharge pipe and motor, just remove the middle coupling of the extended coupling, can exit the rotor part for maintenance.

3, the pump shell (that is, the pump body and pump cover) constitute the working chamber of pump . Impeller, shaft and rolling bearings for the pump rotor. The suspension bearing parts support the rotor part of the pump, and the rolling bearing receives the radial force and axial force of the pump.

4, in order to balance the axial force of the pump, most of the impeller front and back are set with sealing ring, and in the impeller back cover plate is set with the balance hole, because some pump axial force is not big, the back of the impeller is not set with sealing ring and balance hole.

5, pump axial sealing ring is composed of packing gland, packing ring and packing, etc., to prevent air intake or a large number of water leakage. If the impeller of the pump is balanced, the cavity with soft packing is connected with the suction inlet of the impeller. If the liquid at the inlet of the impeller is in a vacuum state, it is easy to take in air along the surface of the shaft sleeve. Therefore, packing ring is installed in the packing chamber through the hole on the pump cover to lead the pressure water in the pump to the packing ring for sealing. Pump impeller such as no balance hole, because the back of the impeller liquid pressure is greater than atmospheric pressure, and there is no air leakage problem, so can not install packing ring.

6. In order to avoid shaft wear, shaft sleeve is installed at the part where the shaft passes through the packing chamber for protection. There must be an o-ring between the shaft sleeve and the shaft to prevent air intake or water leakage along the matching surface.

7. The transmission mode of the pump is connected with the motor by lengthening the elastic coupling. The rotation direction of the pump is clockwise from the driving end.

Model meaning

For example: IS80-65-160 - a

IS- single stage single suction centrifugal pump

Suction inlet diameter (mm)

65- outlet diameter (mm)

Nominal diameter of impeller (mm)

A- impeller cutting mark

| Flow rate | 2-400m3/h |

|---|---|

| Head | 3-125m |

| pump material | cast iron or stainless steel |

| centrifugal pump | transfer pump |

| circulating pump | irrigation pump |

| booster pump | cooling pump |

| supply water pump | feed pump |

| china pump | kenshine-pump |

Retaled category: Centrifugal Pump

Hot search: centrifugal pump, transfer pump, circulating pump, supply water pump, feed water pump, booster pump