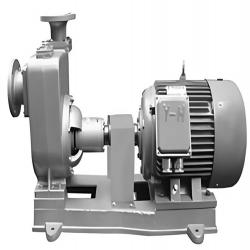

VSP Strong vacuum self priming pump

- Model Number: VSP-50B

- Brand Name: kenshine-pump.com

- Place of Origin: Shanghai, China

- Minimum Order Quantity: 1set

- Supply Capacity: 1000sets per month/month

- Payment: T/T in advance

- MemberShip: Free Member

- Inquiry Now

VSP-50B VSP Strong vacuum self priming pump Description

VSP Strong vacuum self-priming pump:

The VSP self-priming pump is mainly composed of the pump body, pump cover, the rotor assembly and the power assembly. The rotor assembly is installed in the pump chamber composed of the pump body and the pump cover. The power assembly drives the rotor assembly to rotate. Its advantage is strong self-priming performance. The suction height is up 8.2 meters, far higher than other self-priming pump (3 to 4 meters suction range).

The viscosity of pumped liquids is with wide range. VSP Strong vacuum self priming pump can used to convey the volatile solvent and high viscosity oil glue. The liquids in the barrel can be sucked fully, with better suction than that of the vacuum unit. The liquid in the barrel can be sucked up in 1 second after the liquid is pumped out and then insert the pump into the next barrel. Self-priming time is very short. (3 m in 2 seconds). While other self-priming pump need more time (3 m in 180 seconds). VSP strong vacuum self-priming pump has the strong cavitation resistance. Moreover, it has simple structure, few parts, easy installation, easy maintenance and long service life.

VSP strong vacuum self - priming pump

1. Strong self-priming ability: unique and innovative structure, with a suction height of 8.2m.

2. Short self-priming time: 3m /2 seconds, 5m /8 seconds, 8m /15 seconds.

3. Wide range of pumping: volatile solvent and high-viscosity liquid can be pumped.

4. Strong cavitation resistance: the liquid in the high vacuum container can be pumped.

VSP stainless steel explosion-proof strong vacuum self-priming pump

1. Various low specific gravity, volatile solvent solutions and extraction and transportation.

2. Barrel liquid extraction and delivery (instead of barrel pump).

3. Clean the residue inside the tank.

4. Extraction and cleaning of sludge at the bottom of tank and tank.

5. Agricultural, pharmaceutical, intermediates and other chemical industries.

6. High viscosity liquid extraction and transportation in cosmetics, oil and other industries.

7. Beer, rice wine and other brewing related industries.

8. Dairy, dairy and other food-related industries.

9. Pump material: stainless steel or fluoroplastic (F46)

| flow rate | 2-200m3/h |

|---|---|

| head | 2-40m |

| pump material | stainless steel, fluoroplastic |

| self priming pump | chemical pump |

| transfer pump | circulation pump |

| stainless steel pump | fluoroplastic pump |

| acid pump | alkali pump |

| kenshine-pump | china pump |

Retaled category: Centrifugal Pump

Hot search: chemical pump, transfer pump, self priming pump, corrosion resistant pump, fluoroplastic pump, circulation pump